But let’s start with: What is Industry 4.0?

What are the advantages and challenges and how can I use it successfully in the field of ZfP and LED UV lamps?

What is Industry 4.0

Industry 4.0 enables machine-to-machine communication. The focus here is on the Internet, not on computers, as was the case with Industry 3.0. The term “Internet of Things” is also closely related to Industry 4.0, which emphasizes the networking and sometimes self-sufficient communication of individual products and components with each other.

What stages of development have been completed from Industry 1.0 to Industry 4.0?

- Industry 1.0: since about 1800. Mass production by machines such as looms, steam engines and much more.

- Industry 2.0: since the end of the 19th century. Chord and assembly line work as well as the beginning of globalization, automotive production and much more.

- Industry 3.0: from about 1970. The foundation was laid by the first Z3 computer by Konrad Zuse in 1941. Further automation through electronics and IT

- Industry 4.0: Digitization of previously analogue technologies as well as integration of cyberphysical systems. Just-in-time production, individual products in mass production

Source: industrie-wegweiser (german website)

Industry 4.0 is characterized by a wide range of possibilities, such as:

Flexible production: involving several companies in the production of a product, better coordination through digital networking

- Convertible factory: modular construction of production lines, individualized products from 1 piece are made possible in the factory

- Customer-centric solutions: smarter, more customer-focused products

- Optimized logistics: improved goods flow

- Use of data: Use of intelligent sensors and data analysis, keyword “big data”

- Resource-efficient circular economy: View complete product lifecycles including recycling of materials

Due to this increasing digitalization, interfaces and standards are becoming increasingly important in order to achieve smooth networking.

Source: plattform-i40.de

Industry 4.0 as a film simply explained (german video):

What are LED UV lamps?

A more detailed overview with a lot of detailed information can be found here: What are UV-LED luminaires

Future viability of LED UV lamps for Industry 4.0

The mere fact that LED UV lamps consume an energy requirement of roughly less than 10 percent compared to the usual halogen equivalents make them an economic and ecological ray of light in the truest sense of the word.

LED UV lamps – modern technology for Industry 4.0

LED UV lamps are designed with light-emitting diodes and are based on semiconductor connections that convert current into light. This makes electronic monitoring possible. The LED-UV technology is therefore significantly more manageable than conventional discharge-based mercury vapor lamps.

This means that LED UV lamps are used in established industries, e.g. to cure paints, adhesives or silicones. The LED UV lamp technology also has a firm place in the printing industry, for special coatings but also in aviation.

LED UV lamps emit little heat. This has the advantage that a smaller test distance to the test object is thus possible. This saves energy and allows the LED UV lamps to be used for applications that previous UV lamps were not able to use. This also makes it possible to use applications such as offset printing and other printing techniques such as textile printing (screen printing, flex printing) and digital printing on a wide range of surfaces.

Especially the SECU-CHEK UV LED lamps inspire with their modular design. In this way, almost any number of stationary UV LED Floodlightn can be connected to illuminate the desired area for testing. Also in the field of mobile UV LED lamps, tests with battery and hard-to-reach areas are now possible. Depending on the industry and industry, completely new opportunities are generated.

As a stationary application, do you still need flexibility for the alignment of the UV LED lamp? Then the so-called Magic arm from SECU-CHEK is used, with which the user has two hands free during the test, but at the same time can flexibly align the UV LED lamp and position it optimally on or around the test object.

Overview of the four major topics within Industry 4.0

- Internet of Things: already today, various products are connected via the Internet. This development will be significantly strengthened in the wake of Industry 4.0 and will ensure an even closer connection between various software solutions and products, e.g. LED UV lamps.

- Industrial Internet of Things: here the term “Internet of Things” is projected on to industrial production plants. This will ensure even greater automation. At the moment, this point is not very pronounced.

- Cloud computing: To store data in the cloud and to be able to use software solutions directly from the cloud or as Saas “Software as a Service” from a system. The other decisive development steps will be the establishment of standards, which is to be done e.g. through the Industry 4.0 platform.

- Big Data: The currency of the future is information. As futuristic as this sentence sounds, it is already noticeable in the early days, if you look at the business models of large young tech companies. Due to a more performant system and artificial intelligence (AI), in the course of digitization with Industry 4.0, there will be insights that would never have been conceivable or feasible without the corresponding algorithms.

Industry 4.0 and safety with LED UV lamps

Test methods in which LED UV lamps ensure safety:

ZfP (Destruction-free material testing): here the parts to be tested remain intact and can continue to be used in live operation. This is an enormous safety factor, as the test objects such as brakes, engines, engines and other safety-relevant parts can be properly examined at regular intervals with the LED UV lamps and the corresponding ZfP process:

- Visual inspection (VT – visual testing)

- Color penetration testing (PT – penetrant testing)

- Magnetic powder testing (MT)

Industries where these test methods are used with LED UV lamps

Industrial sector:

– Welding seam testing

– Forged part test

– Casting testing

– Serial part inspection

– Goods receipt check

– Procedural examination

– Leakage testing

– Penetration test

– Chassis components

– Wheel set shaft testing

– Rail testing

Aerospace:

– Engine testing

– Suspension testing

– Turbine testing

as well as in research, medicine, forensic science, building, safety technology, hygiene,in the automotive industry and many other areas as well as mineralogy, geocaching or testing of suction systems.

LED UV lamps from SECU-CHEK are characterized by a particularly high intensity and uniform illumination. This means that the best possible displays and thus consistently safe test results are possible.

This is why LED UV lamps improve the test process itself and protect the user:

UV light is emitted only as UVA radiation and not UVB and/or UVC radiation

- the high light intensity from the light beam especially for SECU-CHEK LED UV lamps ensures a relaxed working

- the eyesight is as spared as possible by the special UV-Formity technology,which ensures a particularly homogeneous illumination area

- the adaptation time signaling informs the user if his eyes have adjusted accordingly, so that even possible errors can be reliably detected

- the LED UV lamps are ready immediately after switching on, reducing the risk of misinterpretation due to incorrect handling

In this way, LED UV lamps significantly minimize the risk of errors and improve production conditions for many people.

Flexibility thanks to SECU-CHEK LED UV lamps for industry

- the LED UV lamps from SECU-CHEK are designed to be flexible and modular: together with you as a user, we design the model that is perfect for your application.

- for example, the H1 LED UV lamp model for mobile applications can be used to create over 45 adjustments/variations for different working conditions and requirements

- a system, many possibilities for your individual LED UV lamp:

- Number of LEDs

- choose the right certifications for your LED UV lamp from all common LED UV standards

- Illumination: as Floodlight or focused

- Combination of several LED UV lamps as a large Floodlightunit possible

- Etc.

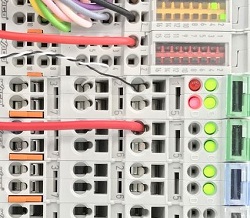

Intelligent PLC control and analysis functions for SECU-CHEK LED UV lamps for Industry 4.0

The right LED UV lamp for every wasteland and all needs is possible, among other things, because SECU-CHEK has developed an intelligent PLC control system.

This combination of PLC and LED UV lamp turns Industry 4.0 into reality:

- no matter which industry: in the ZfP/visual testing, the centerpiece is always the right LED UV lamp with a complex programmed PLC control. This ensures an intelligent but too easy-to-use LED UV lamp for practical operation in industry.

- SECU-CHEK develops and manufactures LED UV lamps and has developed a modular system so that the perfect solution is always possible to meet the individual requirements

- Thanks to state-of-the-art production processes as well as highly qualified employees and experts for ZfP with many years of practical experience, SECU-CHEK

UV LED lamps in terms of performance, service life and quality the maximum and SECU-CHEK is thus in the forefront of LED UV lamp manufacturers.

T

With SECU-CHEK as a partner, anything is possible.

LED UV lamps from SECU-CHEK combine these aspects. With SECU-CHEK LED UV technology, you are always “State of the Art”.

Cost-effectiveness of LED UV lamps

- LED UV lamps enable comprehensive analysis and monitoring functions thanks to the individually programmable PLC power control for Industry 4.0

- SECU-CHEK LED UV lamps indicate early if there is a problem with one of the UV LED modules and switch off for safety when a critical limit is exceeded

- low maintenance costs compared to conventional LED UV lamps (especially mercury vapor lamps)

- Avoid costly downtime

- Lower energy consumption due to the unique eco-mode (advantages of eco-mode)

LED UV lamps from SECU-CHEK for Industry 4.0

- The years of experience in theory and practice flow into the LED UV lamps through the specialists and scientists of SECU-CHEK

- the PLC-controlled LED UV lamps are designed for the highest demands such as the aviation industry and are characterized by excellent properties for the user in practice as well as from the business figures

- SECU-CHEK offers customized solutions for LED UV lamps from a single source. In this way, we solve your challenges on a project-by-project basis, so that you have only one contact person and can thus rely on the most efficient implementation of your projects.

- LED UV lamps from SECU-CHEK are offered worldwide in direct sales. As a customer, you thus benefit from the highest possible level of expertise and solution compotence for your individual requirements. At the same time, we offer a very lean, cost-effective product without intermediaries. All in the interests of our customers.

We look forward to seeing you!

Do you have questions about Industry 4.0, PLC control or other aspects related to the automation of your projects with LED UV lamps?

We look forward to your inquiry!

You are also welcome to contact us by phone or email.

Direct contact:

SECU-CHEK GmbH

An der Fähre 9

66271 Kleinblittersdorf

GERMANY

Phone +49 6805-942859-0

Fax +49 6805-942859-95

Email: info@secu-chek.de

Flexible production: involving several companies in the production of a product, better coordination through digital networking

Flexible production: involving several companies in the production of a product, better coordination through digital networking

UV light is emitted only as UVA radiation and not UVB and/or UVC radiation

UV light is emitted only as UVA radiation and not UVB and/or UVC radiation